Our

services

Our professionals are available 24/7. When it comes to providing technical advice, supplying spare parts and/or service for all our well-known brands.

We are able to deliver directly our spare parts from the warehouse located in Rotterdam or we arrange deliveries directly from our various manufacturers.

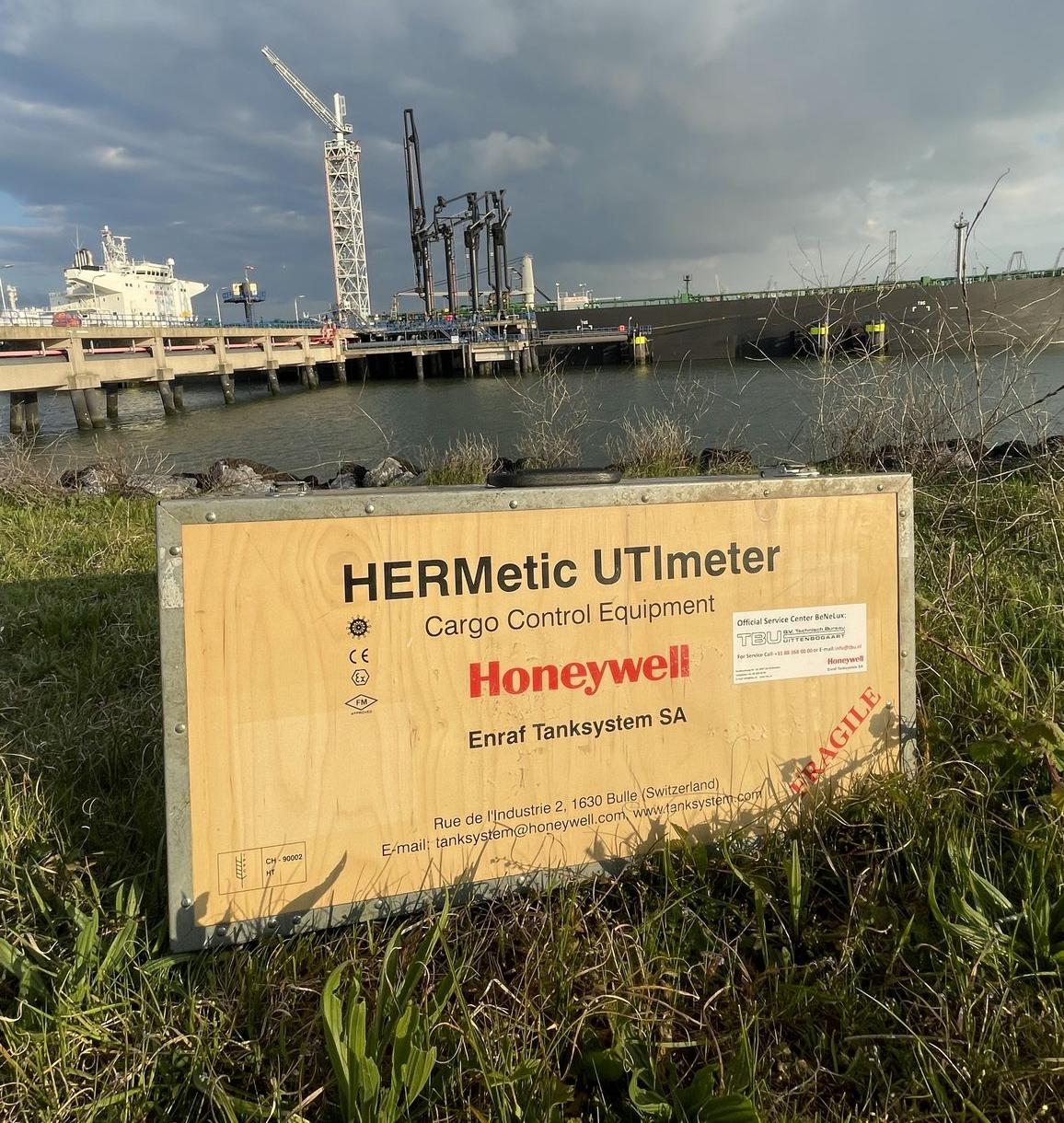

Our workshop is equiped with tools to overhaul pumps, vacuum valves and calibrate and repair 15ppm measuring cells, HERMetic UTI and Samplers and more. According to the latest factory set standards. As service your transport can be arranged to your company's location, agent or directly onboard of your vessel.

We can pickup instruments from board, calibrate them in our workshop and return them, within port stay.

Our experienced service engineers can be deployed anywhere in the world.

When it concerns a shipyard in the Netherlands or a ship moored alongside in Australia it doesn't matter.

Our technicians are continuously trained by our principals.

Contact us, we are at your service, any time any were!

Calibration of 15ppm measurement equipment as we are the official service station of Deckma Hamburg GmbH.

- OMD2005

- OMD24

- OMD2008

- OCD1/2

These unit needs to be calibrated, our service engineers are specialized in these operations and are available 24/7

HERMetic UTI Calibration

- HERMetic GT3

- HERMetic Gtex (Chem)

- HERMetic Gtex HP (Chem)

- HERMetic G2000

HERMetic Sampler repair

- HERMetic Sampler GT-Chem, Portable Closed Sampling Device

- HERMetic Sampler GT GT-Strd, Portable Closed Sampling Device

- HERMetic Sampler GTN Chem, Portable Closed Sampling Device with closed liquid transfer

- HERMetic DIP

- HERMetic Press

- HERMetic OXY

Other brands on request

Do you have any instruments of below maker’s, we can offer you special package for upgrades to Honeywell HERMetic Instruments.

MERSEN: UTL 200

MMC Model: D2401-2 Restricted & Open Type

MMC (ASIA): D2401-2 Closed Type & Gas Tight

TANKTECH KOREA: TKT T2000

Seahover Technologies: SHT2002

Introducing TBU

a name synonymous with excellence in the world of sewage treatment plant maintenance and repair.

With a legacy of innovation and expertise, our dedicated team is committed to ensuring the optimal performance and longevity of your systems.

The TBU Advantage

At TBU, we've cultivated a team of seasoned professionals who have undergone extensive training under the mentorship of leading sewage treatment plant manufacturers. Our collective knowledge, coupled with hands-on experience, equips us to handle a diverse range of maintenance and repair challenges with precision and efficiency.

Our Comprehensive Service Portfolio

Our commitment to excellence is reflected in our comprehensive service portfolio, which goes beyond the ordinary:

1. Visual and Operational Inspections: We meticulously examine every aspect of your sewage treatment system, leaving no stone unturned. Our visual and operational inspections are designed to identify potential issues, ensuring the reliability and efficiency of your plant.

2. Service Reports: We don't just fix problems; we provide detailed service reports that offer insights into the health of your system. These reports serve as valuable tools for informed decision-making and long-term planning.

3. Spare Parts Supply: As part of our commitment to seamless service, we maintain an extensive inventory of spare parts. This ensures that when replacements are needed, downtime is minimized, and your system can quickly return to peak performance.

A Partner You Can Rely On

At TBU, we understand the critical role sewage treatment plants play in ensuring environmental sustainability and public health. That's why we consider ourselves not just service providers but strategic partners in your mission.

Global Reach, Local Expertise

With a global presence and a local touch, we're strategically positioned to serve clients around the world. Our team's expertise extends across borders, ensuring consistent, high-quality service wherever you operate.

Innovation and Sustainability

We're committed to staying at the forefront of technological advancements in sewage treatment. Our dedication to sustainability drives us to explore innovative solutions that can enhance the efficiency and eco-friendliness of your plant.

Your Trusted Partner in Sewage Treatment

In choosing TBU, you're selecting a partner dedicated to the longevity, efficiency, and sustainability of your sewage treatment system. We're not just a service provider; we're your ally in ensuring clean, safe, and environmentally responsible sewage treatment operations. Discover the TBU difference, where expertise meets excellence.

Unlocking 50 Years of Stern Tube Excellence

Welcome to TBU, your trusted partner with over half a century of unrivaled experience, having successfully completed over 50,000 repair jobs.

We proudly stand as industry pioneers in stern tube seal bonding, a testament to our enduring commitment to innovation, quality, and global excellence.

Experience Matters

When it comes to maintaining your vessel, experience matters. Whether your ship is in drydock or at sea, whether it's a routine shaft withdrawal or a complex stern tube seal bonding operation, our decades of expertise are here to serve you.

Our Proven Approach: Stern Tube Service Redefined

At TBU, we redefine stern tube service as a comprehensive, multi-stage process designed to exceed your expectations:

Strategic Planning & Seamless Procurement:

Our collaboration begins with an in-depth analysis of your docking schedule. Leveraging insights from our vast service history and your stern tube seal's condition, we provide expert guidance on the scope of service your vessel needs. Once you decide to proceed, we take charge of coordinating with the superintendent, ensuring a well-timed attendance date, and the prompt delivery of vital spare parts. We also provide a detailed preparation document that streamlines communication between your crew and the shipyard. This proactive approach sets the stage for a swift and efficient job execution.

Stern Tube Seal Mastery: In Shipyard or Afloat

Depending on your unique requirements, we carry out service operations either in the shipyard or afloat. Our primary objective throughout the entire service process is to ease the superintendent's and chief engineer's concerns, providing a seamless, worry-free experience.

Ongoing Support for Optimal Performance:

Our commitment extends beyond the service itself. We offer continuous support and guidance to technical managers and chief engineers, ensuring your system operates at peak efficiency. In case of issues, we stand ready to assist in managing leaks, crisis analysis, and more, ensuring the long-term reliability and efficiency of your stern tube seal system.

Comprehensive Service Offerings:

- Complimentary consultation, technical advice, and troubleshooting.

- We are strategically positioned within the Netherlands

- A dedicated team of experienced marine propulsion specialists.

- Expert stern tube seal professionals.

- A robust one-year warranty on our stern tube seal overhaul service.

- Flexibility to provide services both in drydock and afloat.

- Worldwide service coverage.

- Uninterrupted availability, with our team ready to assist 24/7 to meet your needs.

Experience the TBU Advantage

At TBU, excellence is not just a goal; it's our commitment. Our unparalleled service quality, global reach, and unwavering availability ensure the reliability and efficiency of your vessel's stern tube seal system. With over five decades of expertise behind us, we are here to serve you, bringing the highest standards of service to every project. Choose TBU, where experience meets excellence.

- Portable Gasdetection

- Pressure /Temperature Calibrators

- Alcohol testers

- Pressure/Temperature Gauges

- Multi/Clap meters

- Dynamometers/Loadcells

- Inspection/Service EEBD's

- Inspection/Service Breathing Appartus

- Inspection/Certifying BA Compressor

- Inspection of Fixed Foam Installations

- Inspection/Service of Portable/Wheeled Extinguisher

- Inspection/Service Inflatable Life jackets

- Inspection/Service Chemical suits

- Torque Wrenches

Commissioning of the new installations or maintenance on the existing system.

We can help you with all your needs.

Also with scaling issues in the piping we can help you.

Contact us for more information.